A pair of Stanton Stools is designed and built from low-cost construction lumber using normal woodshop power tools (band saw, wood lathe and drill press). I was inspired to build these stools from an American Woodshop episode here featuring Chad Stanton making his Stanton Stools using hand tools only. Mr. Stanton provides some useful design guidelines but leaves it up to the woodworker to create their own work of art.

Motivation

Like many woodworkers I aspire to build wooden chairs because I regard chair-building as a high form of the woodworking art. This project is an ideal way to build necessary skills for building chairs (especially Windsor chairs) and yields some useful furniture that I will donate to my nieces’ families.

For about $12 I purchased 1 piece of 2″ x 12″ x 10 ft. of Douglas Fir dimensioned construction lumber to build 2 stools. I’m a sucker for woodworking projects that use minimum materials but yield maximum utility from simple design and construction.

Design

The stools were crafted to have a rustic, textured look. Like they were carved with an axe and retrieved from an old barn. The taller stool is 23″ and the shorter stool 17″ in height (typical chair seat height). The splay of the legs (vertical leg angle) was 9 degrees.

Construction

As mentioned in Stanton’s video, it is wise to label individual components and orient the leg end grain to be parallel to the seat grain. Hopefully this alignment allows the pieces to expand and contract together to minimize stress during seasonal humidity changes.

Angle Jig

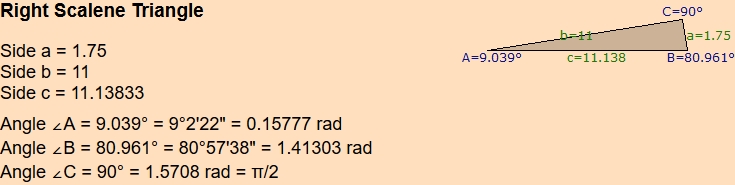

Normally chair-making requires a lot of cutting patterns and jigs to achieve the subtle angles. Here one jig provides an angle to bore the seat and legs. Typical angles are 8, 9, 10 degrees. For an angle of 9.04 degrees Side a=1 3/4″, Side b=11″, as shown below

Tenon Measuring Tool

Being a novice at the lathe I had trouble sizing lathe tenons to fit a mortise snugly. This was attributed to my poor measurement technique using (flimsy) calipers. So I created the tool below by boring 1/2, 5/8, 3/4, 7/8, 1 and 1 1/4″ holes along a common center line and cutting precisely through the centers. This tool proved easy to use and very accurate. If a tenon fit well here, it made for a strong glue joint. A great tool for future chair-making.

I recommend using Titebond Extend wood glue for its longer open time. The stools are finished with Shellac, Cherry Stain and several coats of Polyurethane

Conclusion

This was a fun and worthwhile woodworking project. I progressed my woodworking skills and the stools I made are strong and light and should last a lifetime with my nieces’ families. For my next round of Stanton Stools I would probably forego the seat’s through-hole tenons in favor of a recessed mortise yielding a smoother seat.