Being a dedicated nerd, I’m always fascinated by Proportional Integral Derivative (PID) process control. So when a local farmer asked me to automate a vegetable canning process, I took it as a challenge to physically realize a PID temperature control device. Of course many fine industrial controllers already exist, say from Omega, but I’d already done that so I strived to do it smaller, cheaper. The Arduino product line provides inexpensive hardware for the home Maker. Also, the Arduino development environment is easy to install and remarkably easy to use. For this reason, I decided to build an Arduino PID Temperature Control unit.

About PID

The PID process control method is well researched and commonly applied in modern industry. PID mathematics can be complicated, but (within limits) PID can compensate for thermal resistance and thermal capacitance in a system for precise temperature control. Ideal PID temperature control assumes both a heating and cooling source (with same linear thermal forcing gain). This can be difficult to achieve practically due to different heat/cool technologies. Under-sampling temperature frequently will also increase errors. There are many ways to go wrong. Even when operating correctly, wild oscillations in temperature are possible. Nevertheless PID control can be adapted to many situations.

Many PID controllers claim to autotune the Kp, Ki, Kd PID coefficients to achieve optimal performance. But I suspect these methods are often home-grown and apply only to a narrow set of conditions. PID mathematics is very complicated. Fortunately there are practical manual methods and online simulations to aid in setting these important PID parameters.

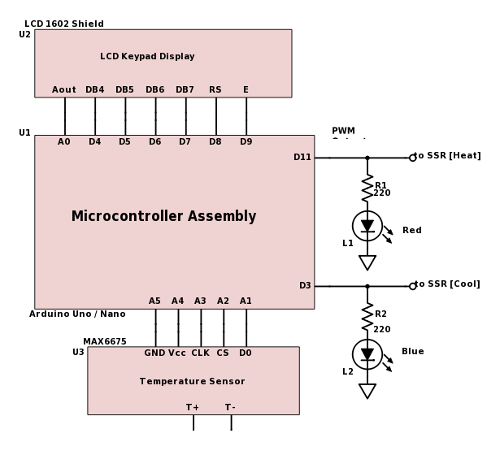

For this controller, the PID proportional output uses Pulse Width Modulation(PWM) on 2 pins. Often PWM is used to create a (time-averaged) variable DC voltage, but here the digital signal duty-cycle modulates a SSR power cycle. One pin outputs the plus(+) and a second pin the minus(-) PID output. The PWM resolution for this microcontroller is 8 bits (0-255 values) for each pin.

Hardware

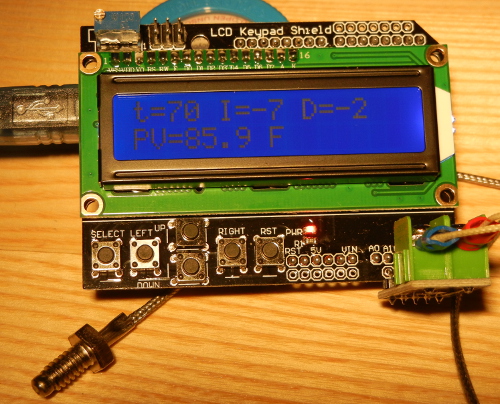

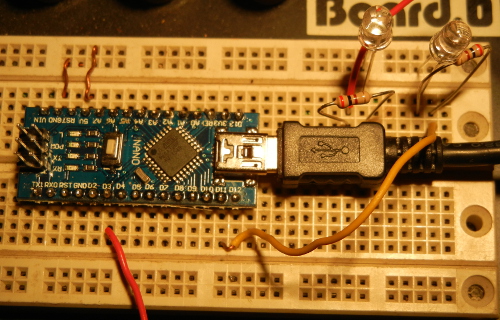

This PID controller device is composed of 3 sub-units (Arduino Uno R3, MAX6675 thermocouple temperature sensor, 1602 LCD keypad display). An Arduino Nano and breadboard was used for testing purposes. Online cost for these units is about $11 + $5 + $4 = $20. Analog pins A1-A5 were converted to digital function for temperature sensor power and communication. Fortunately this leaves digital pins 3, 11 (both on 16 bit TIMER2) to use for PWM modulation outputs.

Program Features

Using the LCD Keypad Display it would be possible to control every function but this is beyond the project’s scope. So the best way to experiment is through the Arduino IDE environment.

- PID output range has units of degrees per sample period . It’s very important to set min/max PID limits for actual physical temperature forcing capability. For example, in a heat-only system the negative PID output is theoretically zero, or perhaps slightly negative (-2 degrees/minute maybe) for an ambient cooling system.

- An over/under temperature Alarm is programmed to terminate execution immediately if min/max temperature limits are exceeded.

- If either +/- PID output limit is reached an error is displayed on the LCD screen. While not fatal, this should be a clue that K coefficients may need adjusting.

- The Arduino Serial Monitor tool displays PID data in progress

- Commenting one line of code switches between PID simulation and live operation

SSR and PWM Problem

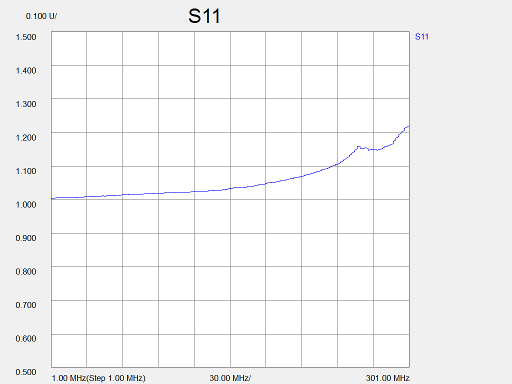

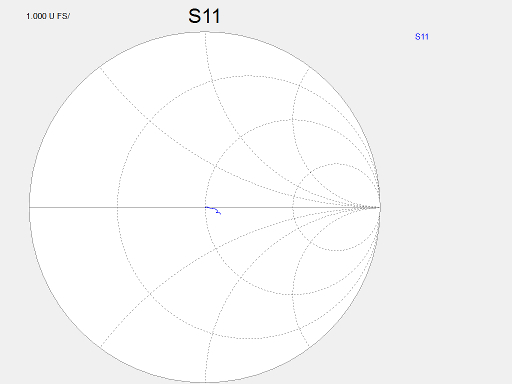

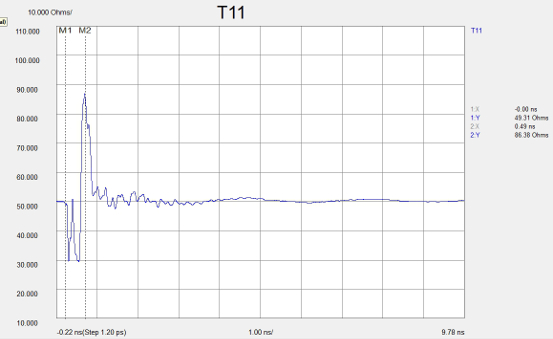

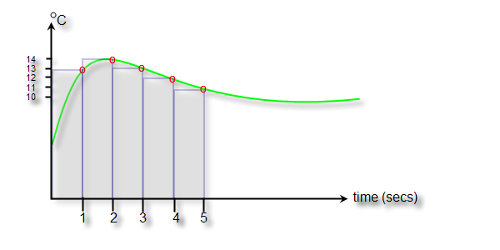

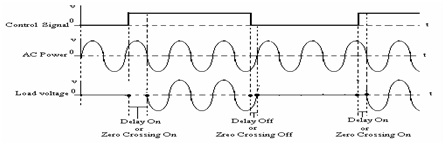

A Solid State Relay (SSR) is capable of switching on/off a 120V heavy load. But, like electromechanical relays, the switching speed is slow. Because common, low-cost SSRs use a TRIAC Thyrister element, the power is not actually switched until the voltage phase of AC power crosses zero. The zero-crossing effect is shown in graphic below.

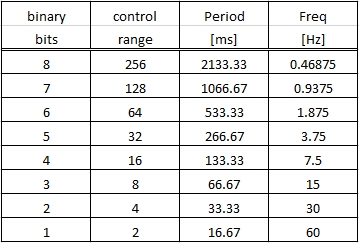

At a frequency of 60Hz the maximum delay is 1/2 cycle or 8.33ms. Considering that our PWM duty-cycle ranges from 0-255, a single bit of resolution at 8.33ms would imply a full range PWM switching period of 256 * 8.33ms = 2.133 sec. By selecting a PWM switching frequency, the control resolution is determined because the SSR only responds to higher order bits. See table below.

Because the ATmega328P master clock operates at 16MHz and the maximum TIMER2 divisor is 1024, the minimum PWM sampling frequency is ~30Hz yielding 4 levels of resolution control. However if we further divide the ATmega328P master clock frequency by 8, then PWM frequency is 3.75Hz with 5 bit (32 level resolution) is achieved.

Considering many practical applications, a sampling rate of ~4Hz with 5 bit resolution was an acceptable trade-off. Implementing both TIMER2 pre-scalar 1024 and master clock divisor 8 is required to reach a PWM frequency of 16MHz/(1024*256*8*2) = 3.83 Hz. The master clock was divided in software with the clock_prescale_set(clock_div_8); instruction which of course has a similar affect on the delay(); instruction and delay values must be divided proportionally. The Arduino standard PID_v1 library was also edited for the same reason and a modified PID_v1R library is included in zip archive link below.

Testing

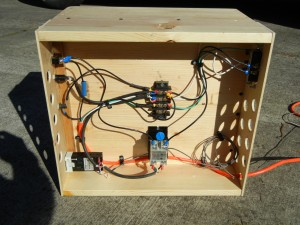

To debug and validate this design an Arduino Nano and breadboard was used with 2 LEDs, SSR and 60W incandescent light bulb. It was easy to see the LEDs flash at a slow rate (PWM cycle time) and the LED brightness change (PWM duty-cycle). The definitive test was using an SSR to switch a 120V resistive load (60W light bulb) and to my joy, flashing and variable brightness was observed. This was the extent of testing.

Discussion

This was a satisfying project because I learned a lot about PID and made a practical PID temperature control unit for very cheap ($20). Almost all the Arduino I/O pins are used and SSR-PWM problems were overcome to a reasonable degree. Adding a menu structure to edit run-time variables from the existing keypad would approach the functionality of a real commercial unit. Adding timer functions could create temperature profiles and recipes(EEPROM). Some practical applications might include a Rice Cooker, Slow Cooker, alcohol fermentation. Some day I’m going to turn the PID problem around and make a device that senses meat temperature and indicates the remaining cooking time. Mom’s Thanksgiving turkey will be cooked perfectly every time.

References

Arduino_PID_Temp_Control_Program.zip

Wikipedia PID

SSR Types